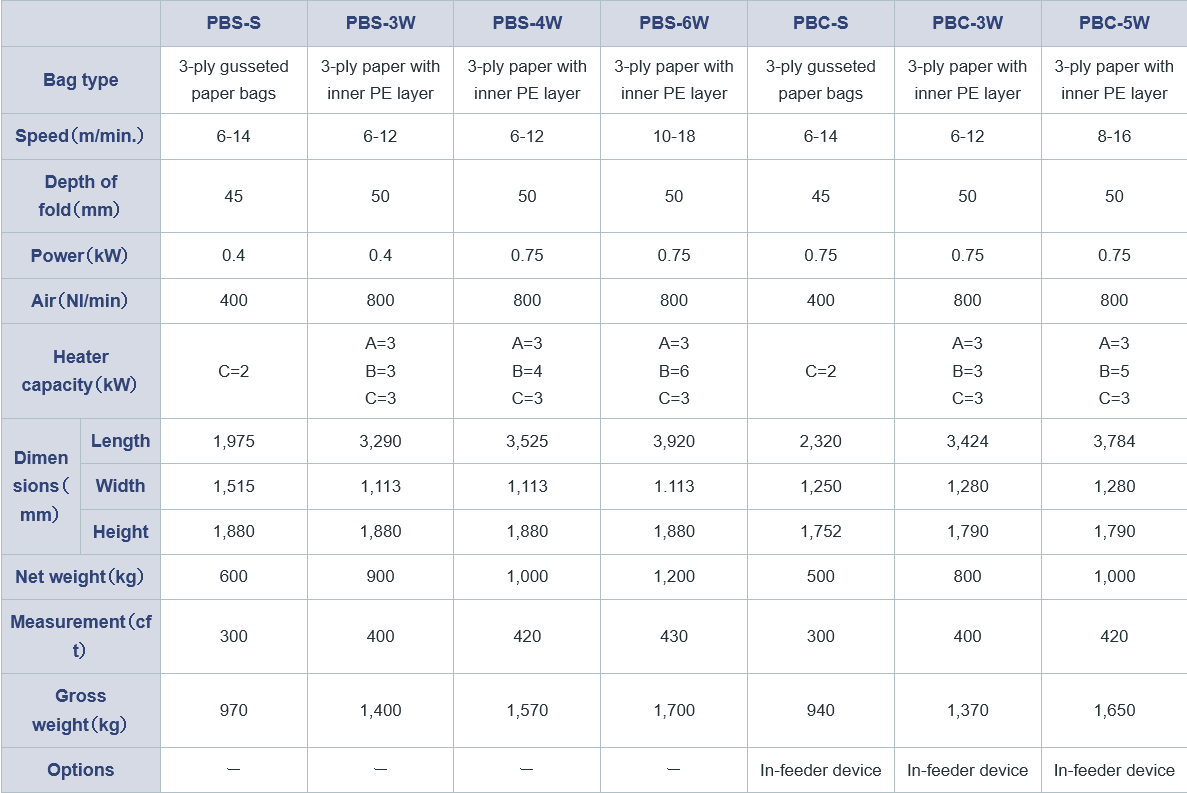

Pinch Sealer

Seals pinch-bags fully automatically

High performance machine for fully automatic closing of double and single pinch-bags

Features

Fully Automatic from Bag Insertion to Closing

Simply insert the leading edge of a bag between the carrier chains or belts. All further operations are done automatically. The PBS Series is the most advanced system for sealing pinch-bags fully automatically in one line.

Seven Variations for Various Bag Specifications

The user can choose the best model according to the products in the bag and the specifications of the pinch-bags. Each of the carrier chain and belt types has single and double variations so that pinch-bags of any specifications can be handled.

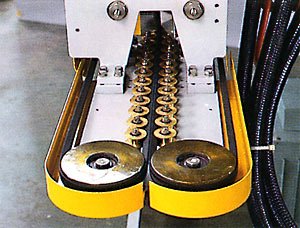

Precision for Enhanced Sealing Performance

Hot-melt glue is completely heated with hot air and is firmly pressed between press rolls to totally seal the bag. For inner PE layer bags,the PE film is first sealed to eliminate moisture and dust entry and prevent degeneration of the products.

Adjustable Heater Temperature

The temperature of both hot air heater and inner layer heater is easily adjustable to suit bag specifications and conditions. Enhanced efficiency and quality packaging are realized at all times.

Ease of Maintenance

Major parts are protected by sealed covers to substantially reduce machine problems. The machine rejects dirt,and maintenance and control of the machine is quite easy.

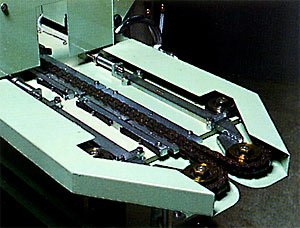

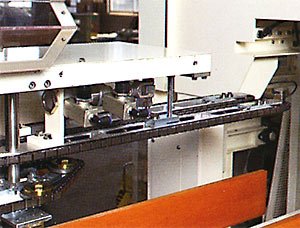

Carrier Chains

Pinch-bags are held between carrier chains at the top,and transported throughout the machine. No possibility of shifting of the sealing position.Bag Support Belt Bags are transported without damage to the surface because they are supported between belts. The belts transport bags positively and smoothly.

Bag Support Belt

Bags are transported without damage to the surface because they are supported between belts. The belts transport bags positively and smoothly.

Infeeder(for connecting the system from an automatic bagging machine)

The guide at the inlet of the machine is used to correctly feed the bags. The leading edge of the infeeder opens to receive bags and then closes to hold and transport them.

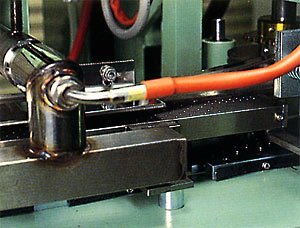

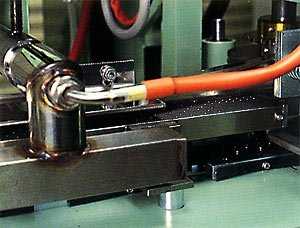

Hot Air Heater(Closer Heater)

Hot air is uniformly blown through a number of small holes to melt the hot-melt glue coated on top of the pinch-bag. The hot air heater is the heart of the pinch sealer and is made most precisely and ruggedly.

Machine Height Adjuster

Machine height is adjustable simply by turning the handle. The entire sealer rises or lowers,and can be locked at the desired height in a very short time.

Imprinter(option)

The ink type imprinter is driven by the pinch sealer. Data or numbers are printed on the same position on each bag. A microswitch and a single-rotation clutch are incorporated. Printing types can be changed with ease.

PBC-3W

For double pinch-bags

PBC-S

Carrier chain type for single pinch-bags

PBS-S

PBS-S

Sealing Process-Pinch-Bag with or without Inner PE Layer

Pinch-Bag(Single Pinch)

Bag top is folded at a right angle. Hot-melt glue is melted by hot air blow. The top is further folded flat on the bag surfaca and pressed and sealed by press rolls.

Single Pinch

Pinch-Bag with Inner PE Layer(Double Pinch)

PE layer is heated by pre-hot air heater and sealed by bar heaters. Hot-melt glue is then melted by hot air blow of hot air heater. The bag top is pressed and sealed.