Top Packaging Machinery Companies to Watch in 2025

Best Packaging Machinery Companies in 2025

In 2025 the most effective packaging machines strike a clear balance: reliable throughput, flexible material handling and measurable sustainability — all while keeping total cost of ownership under control. This article outlines the market drivers, technology trends and selection criteria procurement teams should use when specifying industrial bagging lines, from machine classes and automation to practical buyer checklists.

Key trends shaping packaging machinery in 2025

Design and procurement now respond to four overlapping priorities: automation that stabilises throughput, material-driven sustainability, IoT/AI-enabled uptime and modular designs that shorten SKU changeovers. These priorities shift focus from headline speed to repeatable OEE improvements and whole-life cost. OEMs are delivering systems built for mixed-SKU runs with quick changeovers, traceability and remote diagnostics — backed by investments in sensors, servo drives and modular tooling.

Automation and robotics: how they raise packaging efficiency

Automation and robotics remove repetitive manual work, reduce human error and make production continuous and predictable — lifting effective throughput. Robots take on precision handling while PLCs and servo systems preserve cycle timing and cut variability. Typical gains include lower labour cost, fewer defects and steadier OEE; these solutions commonly pair automated filling and sealing with vision inspection and in-line weighing to close the quality loop.

Sustainability in modern packaging solutions

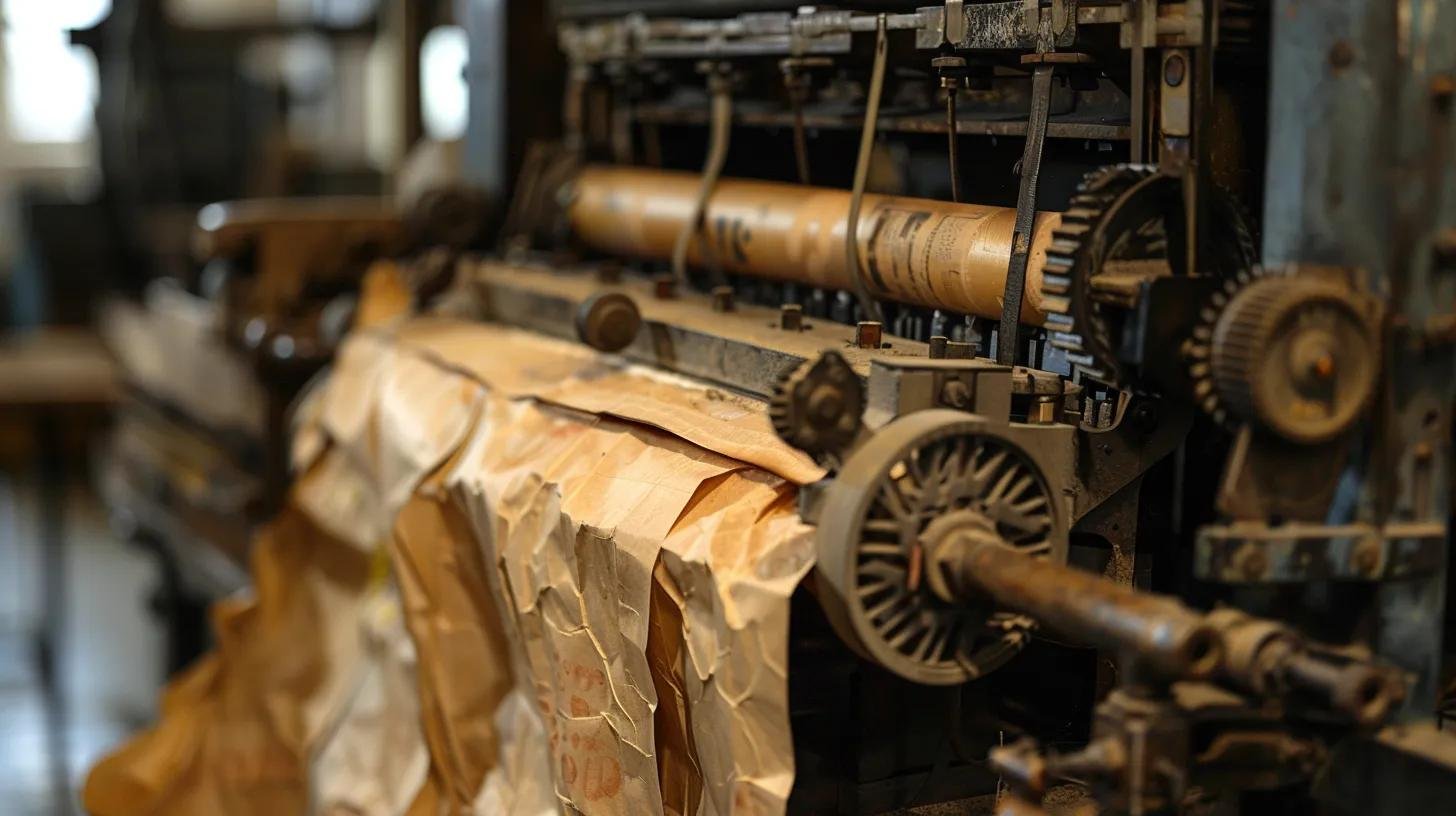

Sustainability now shapes machine design through material compatibility, energy use and waste reduction for recyclable or mono-material formats. Machines must consistently handle paper substrates and thinner recyclable films without compromising seal integrity. Energy-efficient motors and smarter heater control cut operating cost. Buyers increasingly evaluate suppliers on lifecycle metrics — how easy equipment is to retrofit for new materials and how spare parts are stocked and delivered.

Who are the leading packaging machinery companies in 2025?

Manufacturers generally fall into two groups: full-line, high-speed system suppliers and specialised, bag-focused companies. Full-line vendors supply integrated dosing, filling and aseptic options for liquids and FMCG; bag specialists concentrate engineering on bag-making, closing and heavy-duty closures for bulk goods. The practical choice for procurement is scope versus specialisation: select full-line partners for turnkey liquid lines and bag specialists when you need deep material and closing expertise.

Why Newlong Holland stands out in bag packaging

At Newlong Holland we specialise in bag-making and bag-closing machinery for industrial use. As the European branch of Newlong Machine Works, Ltd. (Japan), we manufacture roll-fed and sheet-fed bag makers, heavy-duty closers and automatic bagging machines. Our equipment handles paper, plastic and woven fabrics and is suited to multi-wall paper sacks and S.O.S. shopping bags across food, chemical and agricultural sectors. Customers rely on us for durable design, predictable performance and fast, practical technical support.

How competitors like Syntegon and Tetra Pak compare

Full-line manufacturers such as Syntegon and Tetra Pak focus on integrated systems for liquids and high-speed consumer goods, including aseptic processing. By comparison, bag-focused suppliers concentrate engineering on fibrous and multi-wall paper substrates, heavy-duty sewing and mechanical robustness for bulk materials. In practice, choose full-line vendors for turnkey liquid lines and bag specialists when you need rugged closing technologies and sack-filling know-how.

Essential packaging machinery for industrial applications

Industrial bagging generally uses three machine classes: bag making (roll-fed, sheet-fed, S.O.S.), bag closing (sewing, heat sealing) and fully automated bagging systems that combine filling, weighing and conveying. Bag makers form the container, closers secure the product and integrated systems coordinate the workflow to maximise throughput and reduce manual handling.

Bag-making types: roll-fed, sheet-fed and S.O.S.

Roll-fed machines form bags continuously from a material roll and deliver the highest throughput for uniform substrates. Sheet-fed machines accept pre-cut sheets and offer flexibility for custom formats and heavier stocks at lower speeds. S.O.S. (self-opening style) machines produce gusseted shopping bags and require precise folding and bottom-seal mechanisms for reliable appearance and strength. When specifying, consider changeover time, material waste and tooling complexity.

Advantages of high-speed bag closing equipment

High-speed closers — heavy-duty sewing heads, heat sealers or portable closers — deliver consistent closure quality, cut manual handling and keep line throughput predictable. Reliable sewing or sealing lowers rejects and improves downstream safety, particularly with abrasive or dusty products. Robust closers also reduce operator strain and improve ergonomics. Designs with quick-change wear parts shorten mean time to repair and increase annual uptime.

How automated bagging systems improve packaging operations

Automated bagging systems combine filling, weighing, sealing and conveying into a coordinated workflow that reduces manual steps and increases throughput. They lower reliance on labour, improve batch-to-batch consistency and enable traceability with integrated data capture. Operational benefits include reduced unit labour cost, fewer quality deviations and more efficient use of plant floor space.

Key features of advanced automated bagging solutions

Advanced systems integrate precise filling, automatic indexing, reliable sealing/closing and safety/hygiene features. Core elements include servo-driven infeed conveyors, automatic bag placers, integrated weighing/dosing and robust closing systems. These features cut manual handling, reduce rejects and allow operators to supervise multiple lines from a central HMI. Automatic filling limits giveaway, integrated weighing supports traceability and safety interlocks ensure compliance.

IoT and AI: boosting packaging line performance

IoT and AI improve line performance through remote diagnostics, predictive maintenance and data-driven OEE gains. Sensors stream telemetry to analytics platforms that reveal wear patterns before failures, enabling planned maintenance. AI can recommend recipe adjustments to improve filling accuracy and reduce waste. The outcome is fewer emergency stops, faster mean time to recovery and clearer spare-part consumption patterns, reducing lifecycle costs.

Choosing the right packaging machinery partner in 2025

Choose a partner using a structured checklist that balances technical fit, service capability and total cost of ownership. Evaluate automation compatibility, material-handling expertise, spare-part logistics, retrofit potential and documented support. Key factors include supplier reliability history, spare-part lead times, local service coverage and scalability. After-sales support and customisation options determine uptime — request SLAs that specify response times, spare-part stock levels and training deliverables.

How Newlong Holland is innovating for the future of packaging

We continuously refine bag-making and closing technology to deliver robust material handling, straightforward automation and simple serviceability. Our range — roll-fed and sheet-fed bag makers, heavy-duty closers, automatic bagging machines and heat sealers — targets industries where material durability and dependable closures matter. We focus on durable mechanics, practical interfaces and hands-on technical support.

Sustainable packaging solutions from Newlong

Our machines support sustainability by reliably processing paper-based substrates such as multi-wall bags while reducing waste and rework. Equipment that accommodates recyclable paper constructions and tight sealing tolerances helps minimise rejects and material loss. Our closing and sealing machines are built for heavy industrial use, helping customers reach sustainability targets without compromising production reliability.

Smart technology and automation at Newlong

Newlong Holland supplies automatic bagging machines and systems that integrate into automated lines with minimal friction. Typical automation features include indexed feeds, servo-controlled handling and HMI-based recipe management. Remote diagnostics and preventive maintenance services further reduce downtime and help operators maintain target throughput.

Frequently asked questions

What are the benefits of using automated bagging systems in packaging operations?

Automated bagging systems combine filling, weighing, sealing and conveying to streamline production, reduce manual labour, increase consistency and improve traceability. The result is lower unit labour cost, fewer quality deviations and a more efficient plant layout.

How can businesses ensure their packaging machinery is sustainable?

Choose equipment that consistently handles recyclable materials and runs efficiently. Prefer machines designed for paper-based substrates, with features that reduce waste and retrofit options. Ask suppliers for lifecycle metrics and documented material compatibility.

What factors should be considered when evaluating packaging machinery suppliers?

Consider reliability history, spare-part lead times, local service presence and experience with your materials. Review support packages, scalability and customisation options — these determine total cost of ownership and long-term uptime.

How does IoT integration enhance packaging machinery performance?

IoT enables real-time monitoring and data analysis for predictive maintenance and operational improvements. Sensors capture performance data to spot issues before they cause downtime, while remote access speeds diagnostics and reduces unplanned stops, improving OEE.

What are the key features to look for in advanced automated bagging solutions?

Look for automatic filling, integrated weighing, reliable sealing systems, user-friendly HMIs for recipe management, remote diagnostics and safety interlocks. Modular designs and standardised interfaces to conveyors and palletizers improve flexibility and upgrade paths.

What role does after-sales support play in the success of packaging machinery?

After-sales support is essential for uptime and continuity. Clear SLAs for spare-part delivery, remote diagnostics and preventive maintenance reduce downtime. Good support also helps adapt machines to new materials and raises operator competence, improving lifecycle performance.